It’s a problem as old as Games Workshop. What’s the best way to handle the flight sticks.

I’ve seen breaking off the tip ahead of time because it’s to weak and using a big drill to mount the thick part in the model.

I’ve seen glueing big magnets on both the model and the flight stick to make it work.

I’ve seen people saw a pen housing in half and use that instead of the standard stick.

There’s about a million ways to do it, but this is the way I use so that I don’t have to break anything. It’s all about the drills.

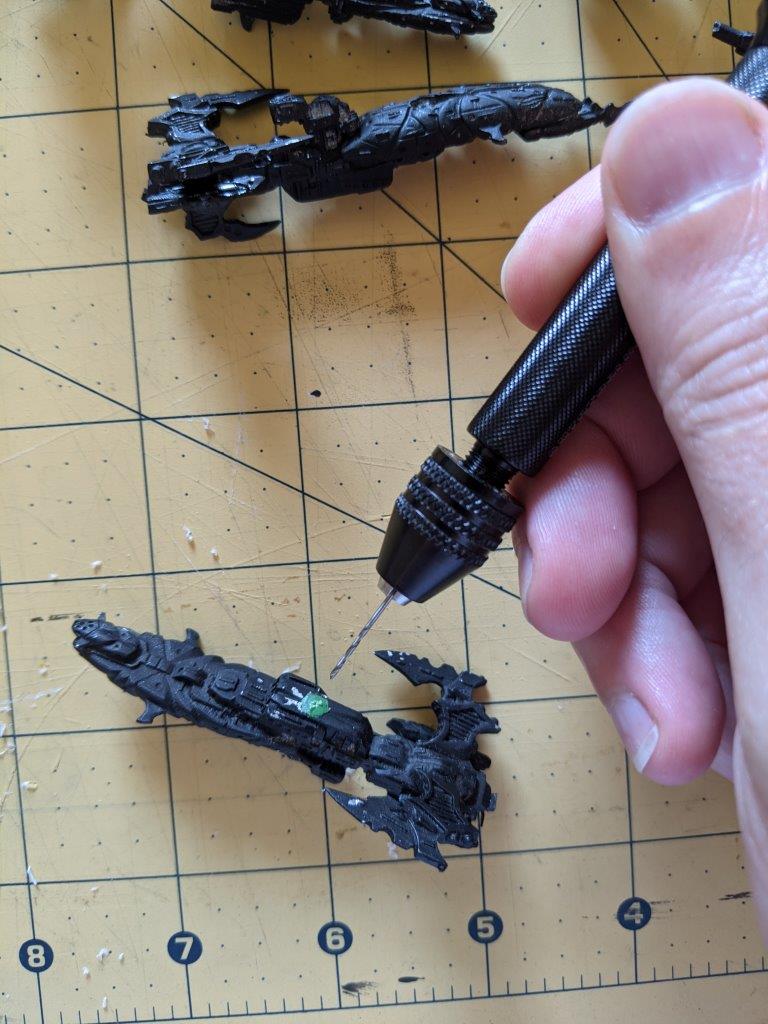

You’re going to start with a pilot drill. This drill is smaller than the hole you’re looking to make. Think of it as marking the location and depth for the hole you want to make.

I my pilot drill is ~1.25mm diameter big enough that it wont break but small enough that I can easily get the location right for the hole.

Use this drill to start the hole in the right place. Sometimes I’ll twist a scalpel blade on the starting point so I’m sure the hole wont wander.

Sometimes you already have a start with the model’s built in ‘hole’ location. You still want to use the pilot drill to set the depth where you want it. Lots of the time you’re fixing a ship with a broken flight stick in it so you’ll definitely want to make the area flat with a file and use a scalpel to mark the location of the hole by twisting it to create a divot.

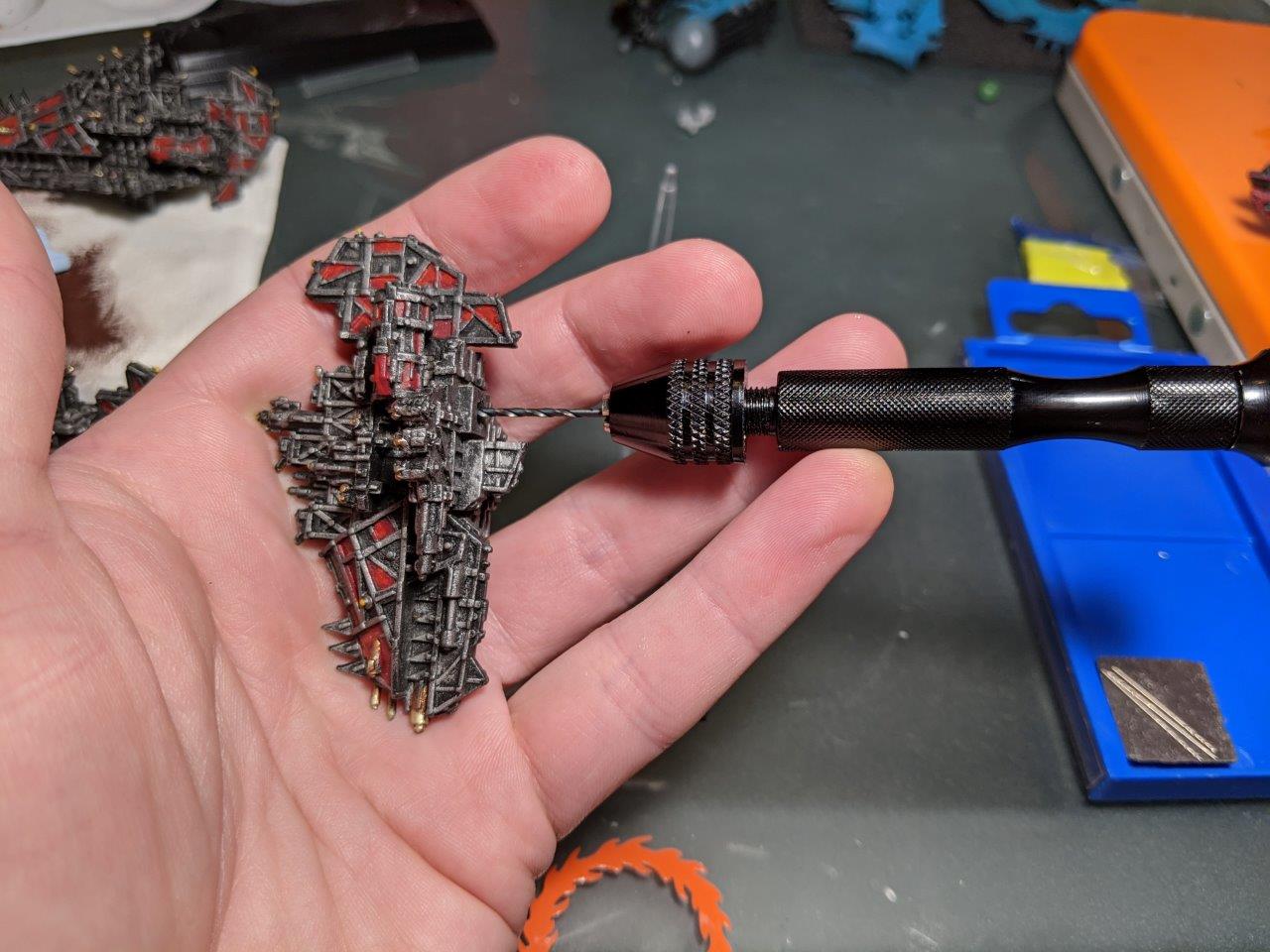

Next up you want to make your ‘finish’ hole. The top of a games workshop flight stick is ~2mm. So you want a 2mm drill bit right? Nope. I messed this up for years. The ships come out free spinning on the top of the flight stick then I have to put stick tack on them to get them to sit still and get the base to come with the ship when I pick it up

You want a slightly smaller bit. So that you get a press fit hole in the ship so you wont need sticky tack.

I use a #47 drill which is ~1.99mm Trust me the .01mm makes a difference.

You can test fit the flight stick at this point to make sure it sticks in there like you want. Tight but not too tight. You should be able to pick up the ship and the base will come with it.

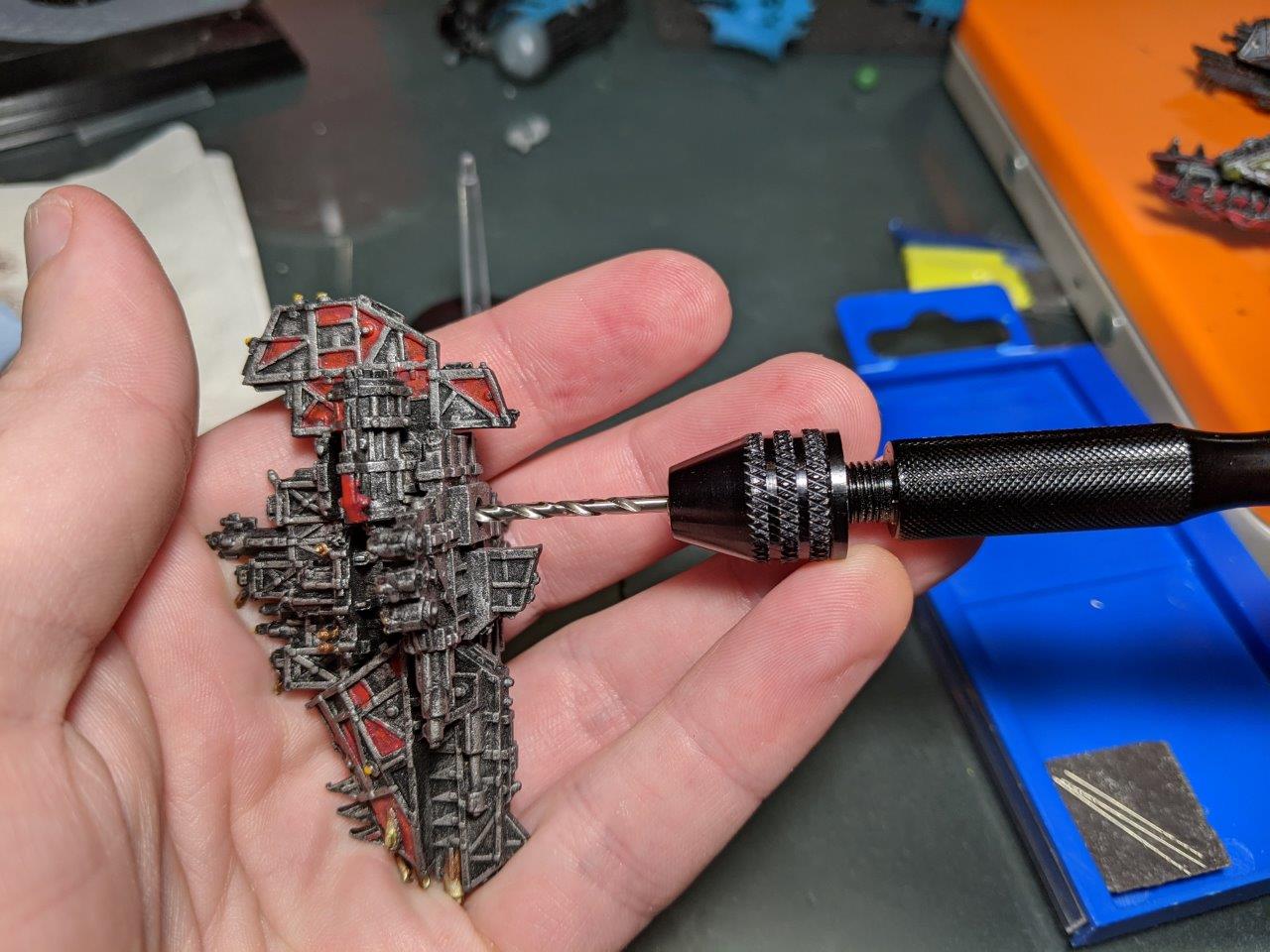

Now what about these big beefie boyz who need more than just a puny 2mm flight stick to hold their girth? You can over drill the depth of the hole and chase it with an even bigger drill bit to hold the thicker part of the flight stem too.

Grab a 3mm drill bit and chase your hole to the depth where the larger part of the flight stick engages. This might take some trial and error to get right because the 2mm hole has to be deep enough to have room for the narrow part of the flight stick, but you can get it to fit perfectly snug.

Final Note: NEVER GLUE FLIGHT STICKS INTO THE MODEL

That is all. Happy Space Sailing